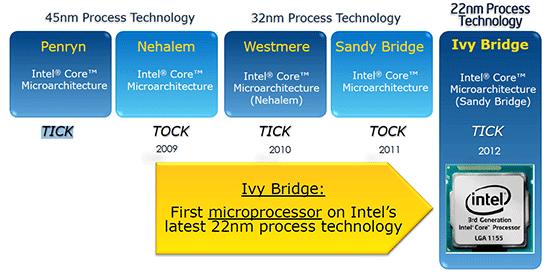

Thanks to improvements in lithography techniques, 10nm CPUs are on the way. Intel has now switched to "process-architecture-optimization" model which essentially introduces a second optimization release to allow for more time to further shrink the processor die. The "tick" part of the schedule was a die shrink and the "tock" was a brand new microarchitecture design. Intel was known for creating the "tick-tock" release schedule for their CPU microarchitecture. The Future of CPU Microarchitecturesĭespite the struggles faced by Intel and AMD to keep up the pace of doubling the transistor count every two years, progress continues to be made, albeit at a slightly slower pace than was previously possible. Kaby Lake was originally meant to be a die shrink, but due to the growing amount of hurdles that comes with dealing with continually decreasing sizes, Kaby Lake was instead optimized at the 14 nm level.

INTEL TICK TOCK RELEASE SERIES

Intel's 14 nm microarchitecture is called Kaby Lake and includes the "7th Gen" 7000 series of processors. Remember, one nanometer is 1/1000 the size of a micrometer, making it substantially smaller than the carbon filament. The current mainstream standard offered by both Intel and AMD is 14 nanometers (nm). We mentioned previously that Intel's first Pentium processor utilized 0.8 μm transistors, which is smaller than the 6 μm carbon filament and is considered large in today's CPU microarchitecture standards. The thicker strand in the image is a piece of human hair and the smaller strand is 6 μm carbon filament. To provide a concrete example, we'll compare CPU transistors to a human hair strand using the above image. Since the release of the Intel Pentium III processor, nanometers continues to be the current size for any and all CPU transistors. "Shrinking a die" is to create an identical circuit using advanced fabrication processes that typically involve an advance lithographic node. The term die shrink, also called optical shrink or process shrink, refers to semiconductor scaling of semiconductor devices, specifically transistors. The processor itself ended up using a mere 180 nm die shrink. Then with the release of the second iteration of the Intel Pentium III processor, the switch was made to nanometer (nm), which is 1/1000 the size of a micrometer. Fractions of a micrometer were the standard die size for a decade. Ever since Intel's first Pentium CPU was released using a 0.8 micrometer (μm) manufacturing process, CPUs have drastically decreased in overall size. Central processing units (CPUs) are constantly becoming smaller and denser, resulting in more power and efficiency.

0 kommentar(er)

0 kommentar(er)